Today, all-pass screen printing-automatic glass screen printing machine manufacturers will explain to you the problems encountered in the process of operating the screen printing machine :

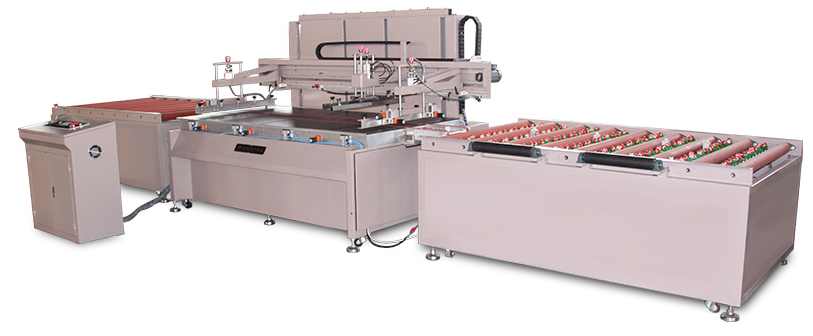

glass screen printing machine

glass screen printing machine

We usually encounter various problems in the process of operating the screen printing machine. The following is an explanation of some of the problems encountered in the operation of the automatic screen printing machine. Distortion of lines: too many screen printings, caused by the relaxation of the screen stencil; the distance between the loose screen and the substrate changes; the angle between the squeegee and the substrate is incorrect, or the force is uneven; the consistency of the printing material is too thin or too dry; After the printing surface of the reworked workpiece is cleaned, the solvent is dried and then silk screened.

Patterns or lines are blurred: the printing material is too thin, and the force of the automatic screen printing machine is too large; the printing material is not evenly adjusted (the solvent in the printing material is not evenly dispersed); The cleaning agent is not dry, or the surface cleaning agent is not dry or not clean when the workpiece is reworked; after the first scraping, the sealing force of the printing material is too large, so that a small amount of printing material is squeezed out of the mesh; the scraper moves (moves) during printing, The speed is too different in the effective area of the substrate, and the printing is stopped in the middle or repeated printing, etc.; the fineness of the printing material does not match the selected screen mesh. Pattern line edge burrs, notches, cams, etc.

The above are the problems encountered in the process of operating the screen printing machine that the screen printing machine manufacturer explained to you.

Post time: Jan-25-2022