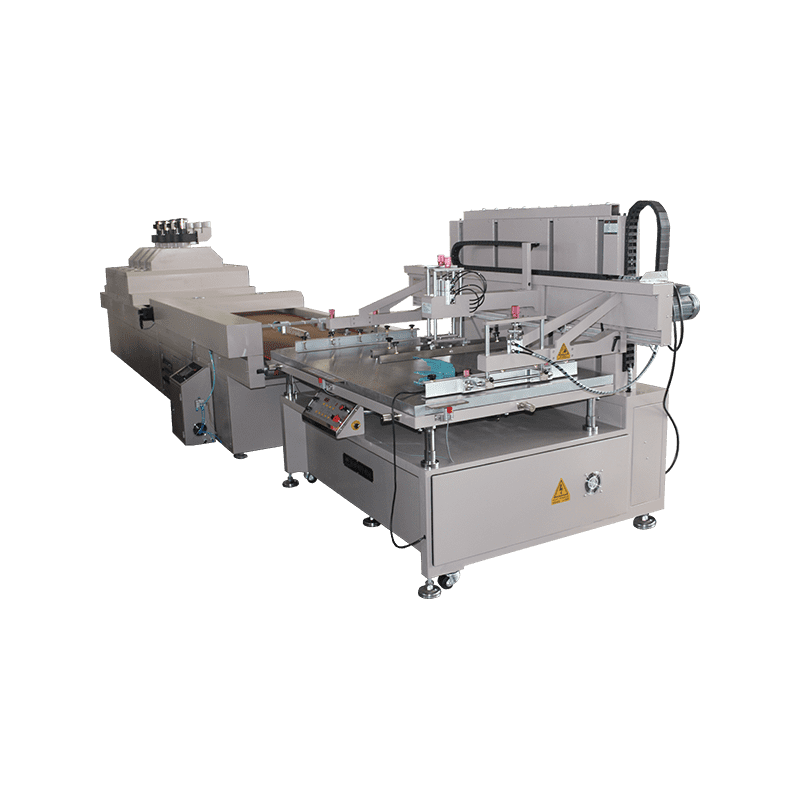

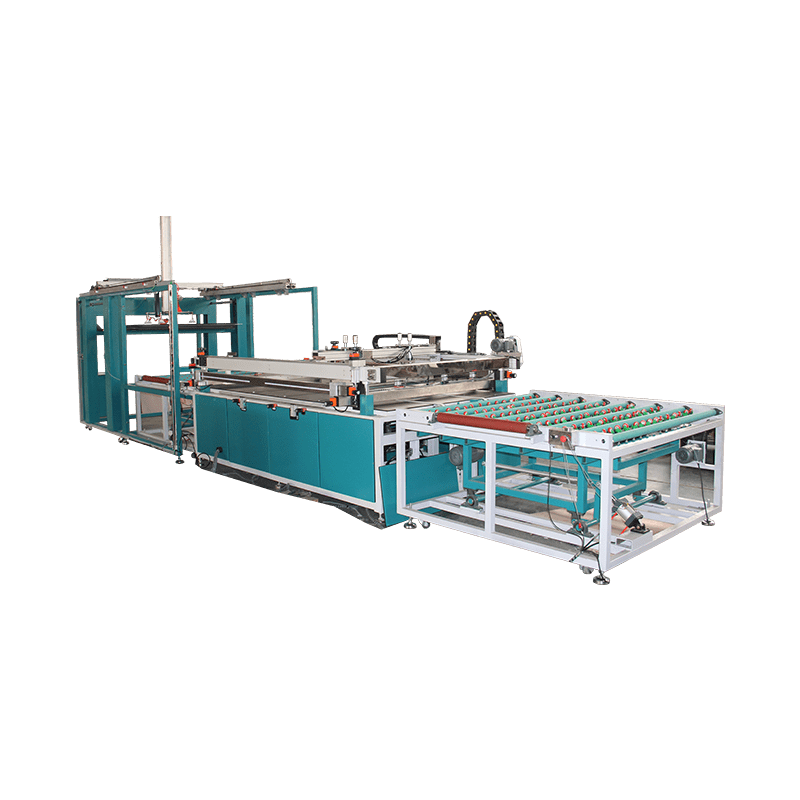

Screen Printing Drying Tunnel Factories - Automatic glass screen printing machine line – Xinfeng

Screen Printing Drying Tunnel Factories - Automatic glass screen printing machine line – Xinfeng Detail:

● Scope of application:

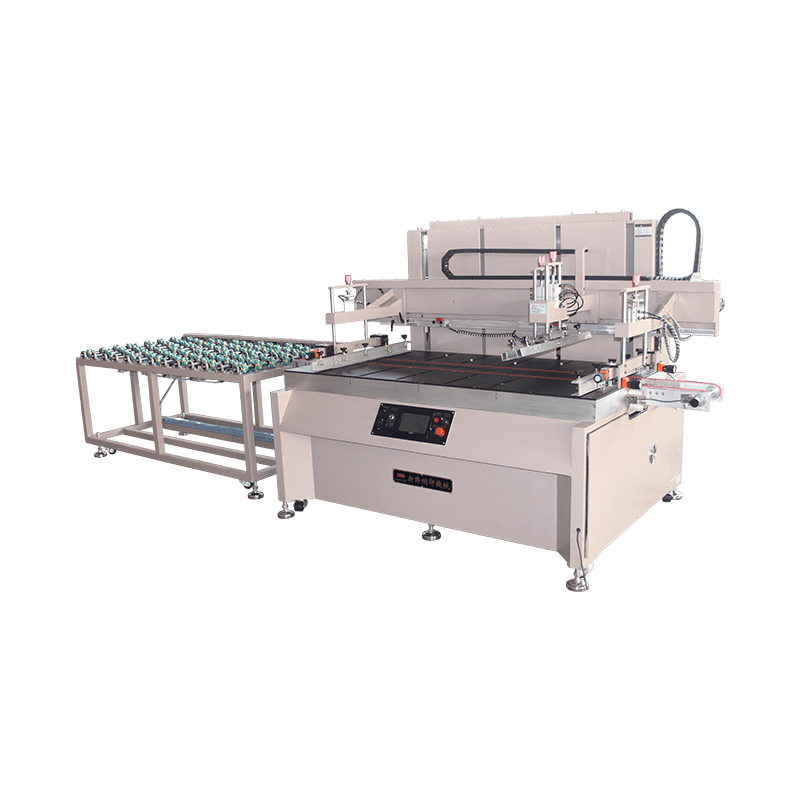

It is a automatic glass silk screen printing machine production line which are suitable for automotive glass/architectural glass/decorative glass and all kinds of large size glass silkscreen printing.

● Feature:

1) The glass silk screen printer is controlled by touch+PLC, From automatically loading→automatically silk screen printing→automatically unloading, Until to drying tunnel, All are automatically realized.

2) Transmission ways

Brake motors of international brands are used. They are delivered to the driving shaft of the stick shaft through the round belt. The wear-resistant and solvent-resistant rubber ring on the shaft of the stick drives the transportation of the glass sheet, The glass in the process of conveying a smooth, safe, and according to need to adjust the delivery speed.

3) Head lift

The head lift adopts the international brand brake clutch reducer to be realized through the chain transmission.Up and down the highest position and the lowest position with dual protection switch to prevent over-lifting damage to the machine and operator safety.

4) Precise positioning

Precise positioning with eight positioning points, the use of two-way cylinder drive (on the drive, horizontal drive), positioning pulley imported rail, with precision ball screw adjustment positioning to ensure accurate positioning is absolutely accurate and equipped with adjustment hand wheel , Position indicator and adjustment locking device. Adjust the distance between the largest glass and the smallest glass

5) Synchronous off-grid structure design.

With the scraping action synchronized frame will be improved, and with a cylinder quick reset device, does not produce shock waves and elastic fatigue. For a variety of different viscosity ink, different tension screen scraping to reduce the shadow, deformation, sticky version to meet a variety of high-precision printing.

6) Scientific control procedure

With the protecting devices, it can prevent the damage to product/machine and operator.

- Parameter:

|

Model |

Max.Glass Size(mm) |

Min.Glass Size(mm) |

Max.Screen Size(mm) |

Printing Table Size(mm) |

Glass Thickness |

Power |

Weight |

|

XF2012 |

2000×1200 |

600×500 |

2800×1600 |

2450×1550 |

2.5-19 |

10 |

3.5 |

|

XF2519 |

2500×1900 |

700×500 |

3280×1800 |

3050×1600 |

2.5-19 |

12 |

4.3 |

|

XF2613 |

2600×1300 |

700×500 |

3380×1900 |

3050×1650 |

2.5-19 |

12.5 |

4.6 |

|

XF2617 |

2600×1700 |

700×500 |

3380×2300 |

3050×2050 |

2.5-19 |

12.5 |

5.1 |

|

XF3020 |

3000×2000 |

800×600 |

3780×2600 |

3450×2350 |

3-19 |

13.2 |

6.1 |

|

XF3725 |

3700×2500 |

1000×700 |

4380×3000 |

4050×2750 |

3-19 |

15.2 |

7.3 |

|

XF4525 |

4500×2500 |

1200×900 |

5280×3000 |

4950×2750 |

3-19 |

18.5 |

8.2 |

Product detail pictures:

Related Product Guide:

It adheres to the tenet "Honest, industrious, enterprising, innovative" to develop new products constantly. It regards customers, success as its own success. Let us develop prosperous future hand in hand for Screen Printing Drying Tunnel Factories - Automatic glass screen printing machine line – Xinfeng , The product will supply to all over the world, such as: French, Guyana, Porto, We follow superior mechanism to process these goods that ensure optimum durability and reliability of the goods. We follow latest effective washing and straightening processes that enable us to supply unmatched quality of items for our clients. We continually strive for perfection and all our efforts are directed towards attaining complete client satisfaction.

Although we are a small company, we are also respected. Reliable quality, sincere service and good credit, we are honored to be able to work with you!