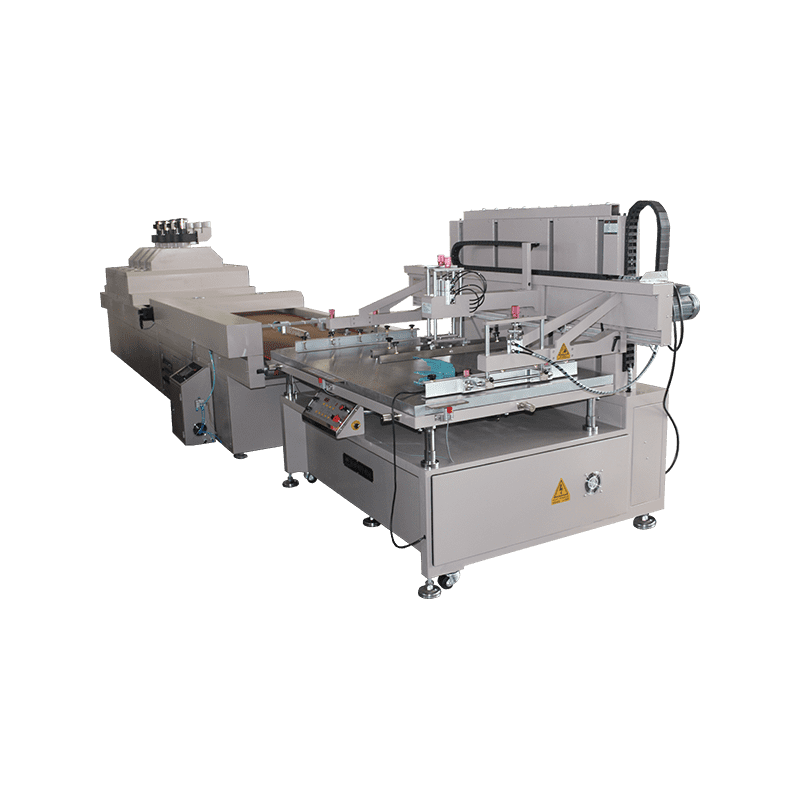

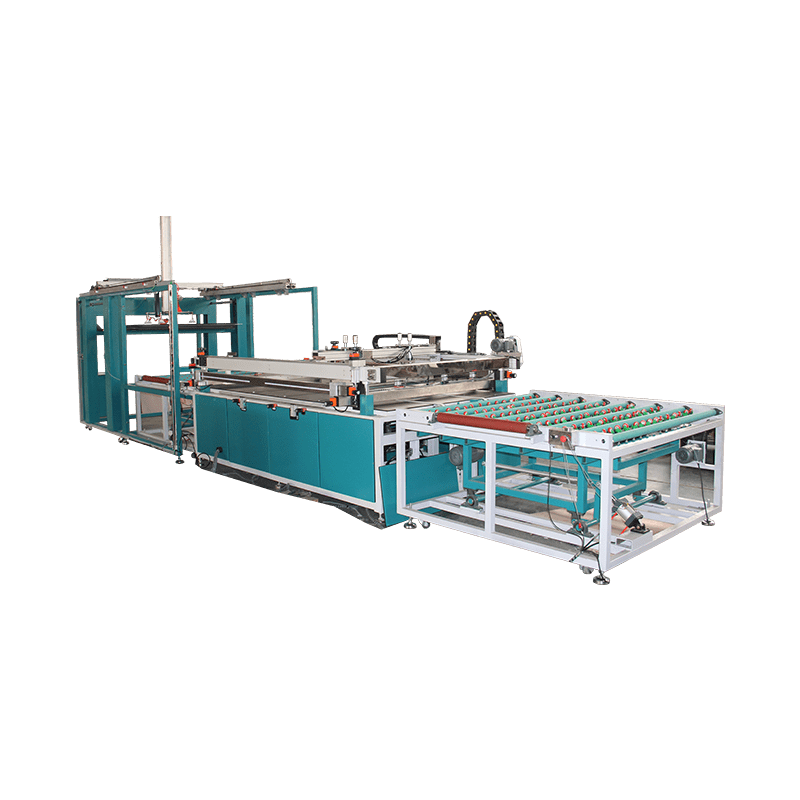

screen printer with auto take-off system

● Scope of application:

This screen printer with auto take-off system are suitable for UV partial varnish, overall varnish, print on metal, glass, wood, paper, plastics, membranes switch, PCB, PET heating transfer film,tempered glass,auto windshield,light guide plate,DC card,nameplate ,also printing on bags,non-woven fabrics, ceramic decals,sticker glazing plate glass, label and panel ,cardboard,corrugated box, refrigerator and air-conditioner decals,plastic sheet,Silicone Paper,Lightbox,traffic sign,plastic bags,acrylic sheet,and other products with the material of PVC/PP, which have high requirement in overprinting

● Feature:

1) It is a 3/4 automatic production line which feeds material to printer by human hand, then takes off material automatically .

2) After the substrate printing , gripper auto take-off system pulling out the printing material, then send it to next working procedure (drying and paper collecting). .

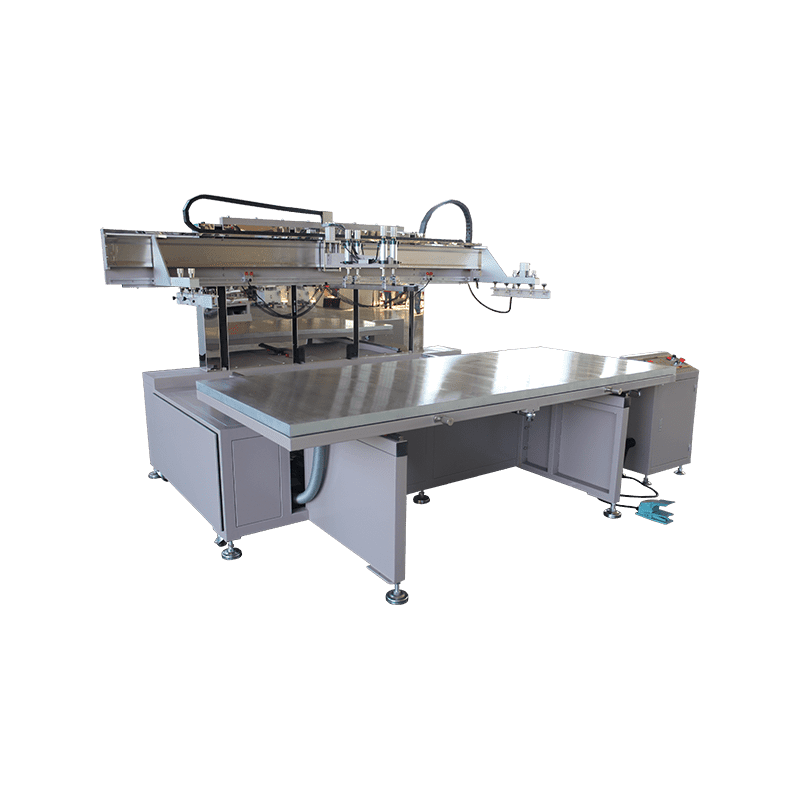

3). The silk screen printer speed of squeegee and flood coater can be adjusted separately.

4). silkscreen printer Synchronous off-contact structure is adjustable for different sizes of frame.

5). High precision vacuum printing table make the printing even .

6). Use top grade linear rail for transmission of printing head and printing table.

7). Safety bar and emergency stop switch for security.

- Parameter:

|

Product Name |

3/4 auto take off screen printing machine |

|

Model |

XF-10200TF |

|

Condition |

New |

|

Automatic Grade |

Automatic |

|

Color & Page |

Single Color/overprinting multi color |

|

Voltage |

380V |

|

Warranty |

one year |

|

Max Printing area |

2000*1000mm |

|

Max Printing thickness |

30mm |

|

Printing frequency(P/H) |

500-700 |

|

Overprint accuracy |

0.01mm |

|

Flat precision |

+-0.05mm |

|

Printing pressure |

0.6-0.8kg/square cm |